|

Product Features |

|

⒈ No aerosol float produced - enhanced biological safety (e.g. branch bacteria, viruses, etc.) |

|

⒉ Eliminates the risk of sample cross-contamination |

|

⒊ Eliminates the traditional problem of probe wear and debris |

|

⒋ Can process a wide range of samples with a broad sample processing range |

|

⒌ Suitable for various standard containers |

|

⒍ Can be used for processing trace samples, as small as 5ul |

|

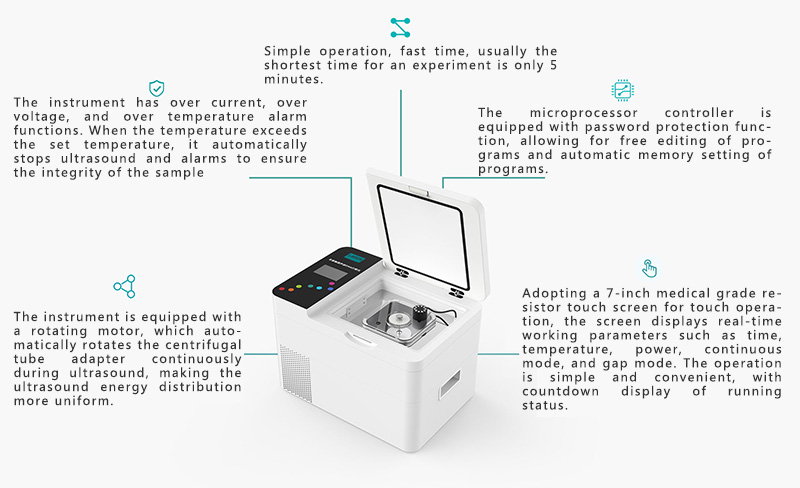

⒎ The automatic continuous rotation of the centrifuge tube makes the energy distribution of the ultrasonic wave more uniform |

|

⒏ Optional high and low temperature constant temperature water bath, customized rotating base for Eppendorf tubes of various diameters according to customer needs |

|

Advantages |

|

|

【1】High throughput, up to 60 samples can be processed simultaneously, with high experimental efficiency. |

|

【2】No frequent operation of the probe is required, and each sample is in a separate fully enclosed test tube to avoid cross-contamination. |

|

【3】The product is equipped with a variety of adapters ranging from 0.1ml to 15ml, suitable for different types of samples. |

|

【4】The ultrasonic parameters can be flexibly set, and the experimental steps are standardized, with good experimental reproducibility and high result reliability. |

|

【5】No special consumables are required, resulting in low experimental costs. |

|

【6】The use of ultrasonic waves in a 4°C low-temperature water bath allows for even energy distribution and complete ultrasonic effects, with samples processed fully in a low-temperature environment to prevent denaturation. |